Tag: Aluminum

-

A Precious Tip

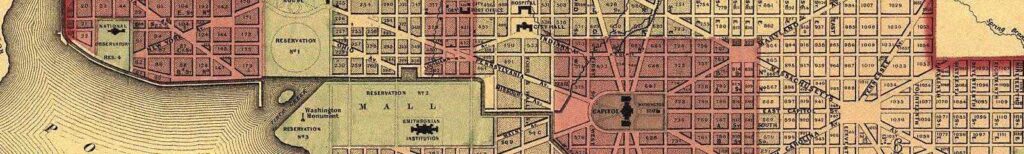

The Washington Monument has been in the news quite a lot lately. Experts continue to examine damage resulting from the 5.8 magnitude earthquake that struck on August 23, 2011. The thought of people rappelling down narrow masonry walls for hundreds of feet searching for cracks seems daunting. Just watch this video from the Associated Press:…